More than 90% of suppressor buyers choose without knowing the key engineering facts. This means many miss out on the top features that make a suppressor stand out.

Choosing the right suppressor is a big deal. It takes time and effort. The best 30 cal suppressors use the latest materials and making techniques for the best results.

When we look at 30 caliber silencers, we check the basics. They need to cut down sound well and last a long time, even after shooting thousands of rounds.

We dive deep into what makes a suppressor great. We look at how well it works and how it’s built. We’ll show you what makes the best suppressors different from the rest in today’s market.

Key Takeaways

- Advanced materials science and precision manufacturing determine suppressor longevity and performance consistency

- Internal architecture design directly impacts sound reduction effectiveness and gas flow management

- Construction quality separates professional-grade units from consumer-level alternatives

- Engineering principles matter more than marketing claims when evaluating suppressor performance

- Real-world testing data provides better insights than manufacturer specifications alone

- Investment in quality suppressors pays dividends through superior durability and reliability

Core Construction Materials and Manufacturing Quality

The quality of a suppressor starts with its materials and how it’s made. These things affect how well it works and how long it lasts. The right materials and making them with care are key to a suppressor’s success.

Quality in making 308 suppressors sets them apart from cheaper ones. It’s about following strict rules to make sure they work right and are safe. Top makers check every step of making to keep quality high.

Titanium vs Steel vs Aluminum Construction

Choosing the right material is key in making a suppressor. Each material has its own good points and bad. We look at things like strength, weight, and how it handles heat and corrosion.

Titanium is the top choice for tactical suppressors. It’s strong, light, and doesn’t rust easily. Titanium suppressors are lighter than steel ones but just as tough.

- Superior strength-to-weight ratio reduces shooter fatigue

- Excellent corrosion resistance extends service life

- High melting point handles sustained fire effectively

- Non-magnetic properties benefit tactical applications

Steel is great for handling lots of heat and heavy use. Steel suppressors can take a lot of abuse but are heavier. This can make the gun harder to handle.

Steel is reliable for 308 suppressors used a lot. It keeps cool during fast shooting. People who shoot a lot often choose steel for its durability.

Aluminum is cheaper but has its limits. Aluminum suppressors work well at first but can’t handle high heat. They don’t last as long as other materials.

Precision Machining and Tolerances

How well a suppressor is made is very important. We check how well the parts fit together. The best ones have parts that fit very closely.

Good machining means the parts work right together. This keeps the sound down and the suppressor working well. Every part must be made just right for safety and performance.

The difference between a good suppressor and a great one is in the tiny details of how it’s made.

Using special machines helps make suppressors the same every time. Quality checks make sure they’re made right. This affects how well they work and how long they last.

Welding Quality and Joint Integrity

Welding is very important in making a suppressor. Bad welds can cause big problems. Good makers use skilled welders and check their work carefully.

Welds must be strong to handle the stress of use. Tactical suppressors go through a lot, so welds must be strong. The welding process must make joints that are stronger than the parts themselves.

Using special welding methods like electron beam welding makes joints stronger. These methods create clean, strong welds. Quality checks like pressure tests make sure the welds are good.

How a joint is made affects how well the suppressor works. Good welding and design mean it will last a long time. We look at welding as a sign of a maker’s skill and care.

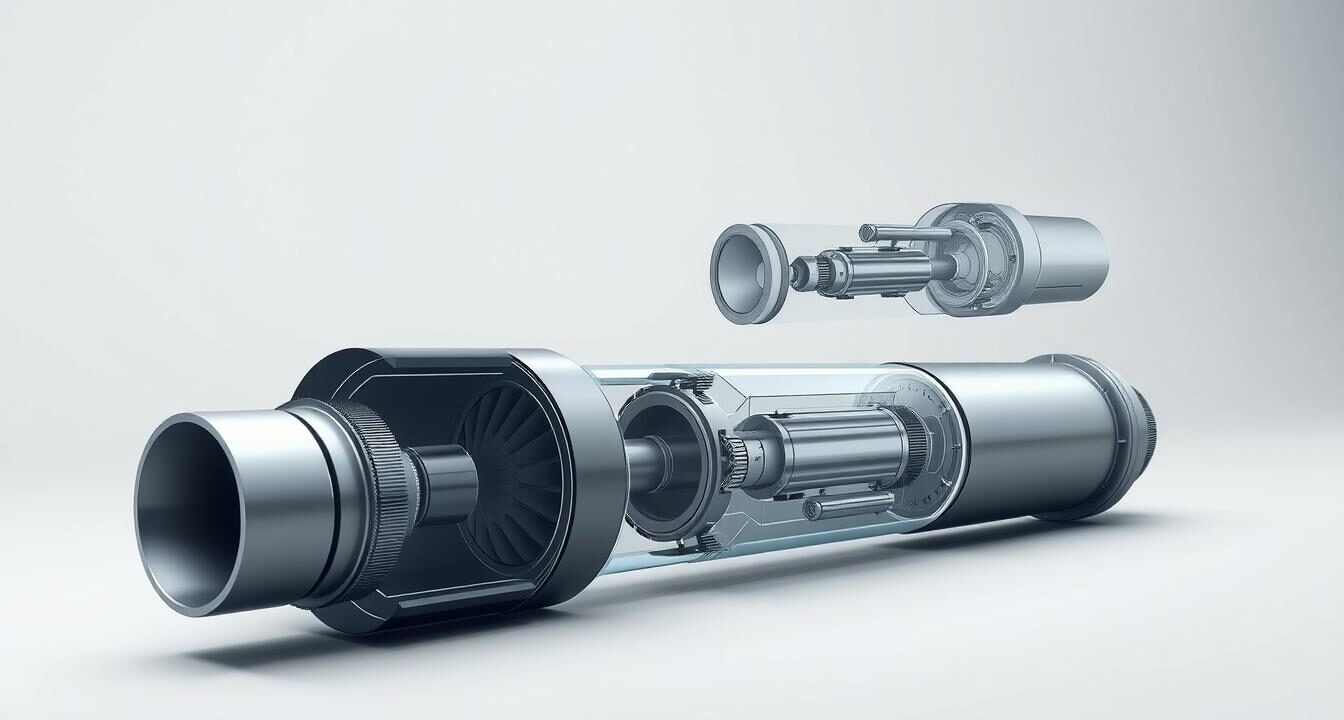

Baffle Design and Internal Architecture

The internal design of a rifle sound suppressor is key to its performance. We look at how baffle systems manage gas to reduce sound. These parts work together to control pressure.

There are three main designs for suppressors. Each has its own benefits for different needs. Knowing these helps us choose the right one.

Traditional Baffle Stack Systems

Traditional systems use multiple chambers in a row. Each chamber helps gas expand slowly. This controls how gas moves.

The shape of each baffle is important. Cone-shaped baffles help gas flow and create turbulence. Flat baffles control gas speed with their ports.

Stack systems have big advantages:

- Parts can be replaced easily

- They can be customized

- They’ve been reliable for years

- They’re affordable to make and fix

These designs are great for maximum serviceability. You can replace parts without getting a new core.

Monocore vs Modular Designs

Monocore systems have all parts in one single component. This avoids alignment problems and ensures gas flows well. CNC machining makes it precise.

Monocore systems are strong and consistent. Integrated design means no joint failures. It also helps with heat.

Modular designs let you change the suppressor length. This is useful for different barrel lengths.

Key differences include:

- Alignment accuracy: Monocore is perfect

- Maintenance complexity: Modular is easier

- Performance consistency: Monocore is more reliable

- Customization options: Modular is more flexible

Flow-Through Technology Advantages

Flow-through technology is the latest in suppressor design. It improves gas flow and pressure reduction. It uses advanced math to design the chambers.

Its main benefit is lower back-pressure. This makes rifles cycle better and reduces fouling. It’s great for semi-automatics.

Flow-through designs also reduce the first-round pop. This makes sound more consistent during firing.

Benefits include:

- Improved cycling for semi-automatics

- Less maintenance needed

- Consistent suppression during fast firing

- Less heat buildup

Flow-through technology offers clear improvements in suppression and reliability. It’s the future of suppressor design, blending old and new ideas.

Sound Suppression Performance Metrics

Sound suppression performance looks at many factors to see how well it works in real life. We test suppressors in detail, not just with simple numbers. We check how they change sound in different situations and with different bullets.

Professional tests show what makes a suppressor good. We look at how much sound is reduced, how long it lasts, and what frequencies are affected. The top suppressors cut down firearm noise well and work reliably in many shooting situations.

Decibel Reduction Capabilities

Good suppressors cut down sound by 25-35 decibels in tests. We use special tools to measure sound levels at the shooter’s ear and further away. This method gives us accurate info on how much noise is really cut down.

Top suppressors work well with all kinds of bullets, not just one type. They keep sound reduction steady, no matter the bullet weight or powder charge. We test them with different bullets to see if they perform consistently.

How much sound is reduced on the first shot is key. We check this because it affects how well a suppressor works in real life. The best ones reduce sound a lot, without losing accuracy or reliability.

First Round Pop Considerations

First-round pop happens when oxygen inside the suppressor makes the first shot sound louder. We measure this because it’s important for real-world use. Many suppressors have 3-8 decibel increases on the first shot compared to later shots.

Advanced designs help reduce first-round pop by managing gas better. We look at how different designs and sizes affect sound. The best ones have little difference between the first and later shots.

How a suppressor is made also matters. We check how precise machining and surface treatments affect gas flow. The best ones have features that stop sudden pressure changes on the first shot.

Tone and Sound Signature Quality

Sound quality is more than just decibels. We look at tone, sharpness, and loudness. The best suppressors make sounds that are lower in pitch and less harsh, making shooters more comfortable.

How a suppressor changes the sound of gunfire is important. We check how different designs shift sound to lower frequencies. This makes the sound less jarring and better for everyone around.

Managing gas flow is key to sound quality. We examine how design and size affect sound duration and harshness. The best suppressors make sounds that are shorter and less disturbing.

| Performance Metric | Excellent Range | Good Range | Basic Range |

|---|---|---|---|

| Decibel Reduction | 30-35 dB | 25-29 dB | 20-24 dB |

| First Round Pop | 1-3 dB increase | 4-6 dB increase | 7+ dB increase |

| Sound Duration | Under 0.1 seconds | 0.1-0.15 seconds | Over 0.15 seconds |

| Frequency Range | Low frequency dominant | Mixed frequency | High frequency dominant |

Multi-Caliber Compatibility and Versatility

We look into how multi-caliber suppressor designs work well with many types of cartridges. These systems are made with advanced engineering. They can handle different calibers without losing their effectiveness. This makes them great for various uses.

Understanding how these suppressors work helps users choose the right one. We dive into how makers achieve top performance across many calibers. They use special designs and strong materials to do this.

Caliber Range Coverage

The best multi-caliber suppressor designs work with cartridges from .223 Remington to .300 Winchester Magnum. They do this by adjusting their internal size and baffle design. This ensures they work well with all types of cartridges.

These systems can handle cartridges within certain size and pressure ranges. They work with .30 caliber cartridges like .308 Winchester and .300 Blackout. This gives users a lot of flexibility.

Advanced baffle designs help keep suppression performance consistent. Makers use special computer models to improve gas flow. This ensures the suppressor works well with all cartridges.

Bore Size Optimization

Bore size is key in multi-caliber suppressor design. It affects both how well the suppressor works and what cartridges it can handle. Makers test and model to find the best bore sizes.

They aim for a balance between bullet clearance and gas expansion. Most designs have bore sizes between .30 and .35 inches. This allows for safe passage of bullets and effective gas expansion.

Baffle port sizes also play a role in gas flow. We look at how precision-engineered port sizes improve suppression. These designs help reduce sound and back-pressure.

Pressure Rating Considerations

High-pressure cartridges need strong suppressors. We check how makers design them to handle different pressures safely. They focus on materials and thickness to ensure reliability.

Pressure ratings show what cartridges a suppressor can handle. Most good ones can handle over 60,000 PSI. This means they’re safe for even the toughest cartridges.

As pressure goes up, keeping the suppressor cool becomes more important. We see how makers use special materials and coatings to handle heat. This keeps the suppressor working well, even during rapid firing.

The best multi-caliber suppressor designs show that being versatile and effective is possible. They are made with careful attention to bore size, baffle systems, and pressure ratings. This gives users flexibility and great performance.

Mounting System Design and Reliability

We look at mounting systems as key to a suppressor’s performance. The link between your 7.62 silencer and gun is crucial for accuracy. It must handle recoil, heat, and repeated use without losing alignment.

Good mounting systems are both easy to use and precise. They need to hold the suppressor tight but also come off easily for cleaning or moving. This balance is hard to achieve, as users and conditions vary.

Direct Thread vs Quick Detach Systems

Direct thread systems are the most secure and concentric mounting method. They thread directly onto the barrel, offering a solid connection. This simplicity means fewer parts to wear out over time.

But, direct thread systems take longer to install and remove. You have to thread it carefully, which can be a hassle with multiple guns. Rushing can lead to cross-threading issues.

Quick detach systems are operational convenience for those who switch guns often. They use a device that stays on the gun, making it easy to swap suppressors. Modern quick detach systems work fast and securely.

But, quick detach systems are more complex. They have more parts that need to work together perfectly. This complexity can lead to reliability issues.

Alignment and Concentricity

Perfect alignment is crucial to avoid damage to the suppressor and injury. Concentricity ensures bullets pass through without hitting internal parts. Even small misalignments can cause problems.

Quality systems keep the bore concentric within 0.002 inches. This requires tight manufacturing tolerances. Temperature changes and repeated use test these tolerances.

We also look at how systems handle heat. As the suppressor heats up, parts expand at different rates. Good systems keep everything aligned despite this.

Repeatability and Zero Shift

Repeatability is key for professional mounting systems. The best systems return to zero within 0.5 MOA after each use. This means you can trust your suppressor without needing to rezero.

Zero shift happens when mounting system tolerances change. Even small changes can affect accuracy at long ranges. Professional users need systems that prevent this.

We judge mounting systems on their long-term performance. The best systems stay precise even after many uses. This ensures your investment keeps performing well over time.

Size, Weight, and Portability Factors

Designing a suppressor is all about finding the right balance. It’s about making it small and light without losing its effectiveness. The size and weight of a suppressor affect how comfortable it is to shoot and how well it performs over time.

Today’s suppressor designs focus on being as efficient as possible. The way a suppressor is weighted impacts how fast you can aim and how steady your shots are over long periods.

Length and Diameter Optimization

Designers look at how long a suppressor needs to be to work well. Short ones, 5 to 7 inches, are easier to handle and don’t throw off the balance of the gun. But longer ones, 8 to 10 inches, can block more sound by having more baffles inside.

The size of the suppressor also matters. A standard 1.5-inch diameter works well for sound reduction and is easy to handle. But bigger diameters might block your view or make the gun too big.

The best suppressor for a 300 blackout rifle needs to handle both fast and slow bullets well. It should be practical to use, no matter the bullet speed.

Weight Distribution and Balance

Where the weight of a suppressor is matters a lot. A heavy front can make aiming slower and cause your muscles to get tired. Good designs try to avoid this by using the right materials and design.

Using titanium can make a suppressor lighter without losing strength, but it costs more. Steel is strong and affordable but needs careful design to stay light. Aluminum is a good middle ground for those who shoot a lot but not too much.

“The best suppressor is the one that disappears from your awareness during shooting, enhancing performance rather than creating handling compromises.”

Overall System Integration

How well a suppressor fits with the gun is key. The best ones work with the gun’s natural feel, not against it. This is very important for precision rifles, where feeling comfortable with the gun is crucial for accuracy.

Mounting systems also play a big role. Quick-detach systems are convenient but add weight and complexity. Direct-thread systems are simpler and lighter but might not work with many guns.

The best 300 blackout suppressors keep the gun balanced while reducing sound. This way, you get better accuracy without losing comfort or practicality.

Durability and Service Life Expectations

Suppressor durability is key to their value and reliability. We look at how different designs and materials hold up over time. The top suppressors keep performing well, even after thousands of rounds, despite the harsh conditions.

Suppressors face tough demands, like extreme temperatures and corrosive gases. These conditions test every part of the suppressor. The materials must withstand the heat and corrosive effects.

Heat Resistance and Thermal Management

Good thermal management is what sets top suppressors apart. We check how they handle sudden temperature changes. The best ones use thermal barriers and materials that resist heat.

Temperature changes cause stress in the suppressor. Materials need to handle this stress without losing shape. Inconel and high-grade stainless steels are better at this than regular materials.

The design of the suppressor also affects heat dissipation. Efficient gas flow helps spread heat evenly. This prevents hot spots that can cause damage.

Corrosion Resistance Properties

Corrosion resistance is crucial in humid or corrosive environments. We test how different materials and coatings stand up to combustion byproducts. Stainless steel alloys and special coatings offer better protection.

Suppressors face challenges from salt air, moisture, and acidic gases. Premium designs use materials that resist corrosion. Surface treatments like Cerakote or nitride coatings add extra protection.

Cleaning regularly helps, but the material quality is key. Suppressors that resist corrosion well look and work better for longer.

Round Count Ratings and Longevity

Round count ratings show how long a suppressor is expected to last. We look at what manufacturers say and real-world tests. Top suppressors can last up to 50,000 rounds before needing major service.

Many factors affect a suppressor’s actual lifespan. Firing rate, ammo type, and how often it’s maintained all play a part. Full-auto rated suppressors are built to last longer with their stronger construction and materials.

How well a suppressor handles repeated stress cycles is important. The quality of its internal surface also matters. The best designs stay in top shape for their whole service life.

| Durability Factor | Basic Design | Premium Design | Impact on Service Life |

|---|---|---|---|

| Heat Resistance | Standard stainless steel | Inconel/high-temp alloys | 2-3x longer thermal cycling life |

| Corrosion Protection | Basic stainless finish | Advanced coatings/alloys | Enhanced environmental resistance |

| Round Count Rating | 5,000-10,000 rounds | 20,000-50,000 rounds | 4-5x extended service intervals |

| Construction Quality | |||

| Standard manufacturing | Precision machining/welding | Improved structural integrity |

Knowing about these durability aspects helps shooters choose wisely. Even though premium designs cost more upfront, they often save money in the long run.

Top-Performing 30 Cal Suppressors in Today’s Market

We’ve looked at the top 30 cal suppressors today. We found the best ones in each price range. Each range has its own benefits and meets different needs and budgets.

Knowing these ranges helps you choose the right suppressor. Each one has its own strengths and weaknesses. They vary in materials, how well they’re made, and special features.

Premium Performance Models

Premium suppressors are the best you can get. They use advanced titanium construction and precise parts for top results. The top models have special baffle designs and the latest in making technology.

These high-end models use flow-through technology and top materials. They cut down sound a lot with little back-pressure. They also have designs you can change for different uses. They work well for thousands of rounds.

Even though they cost more, they’re worth it. They reduce sound by 35-40 decibels and last a long time. They’re made with the best materials and engineering.

Mid-Range Value Options

Mid-range suppressors are great for those who want quality without spending too much. They use proven designs and good materials but cost less than the top models. They’re perfect for those who want great performance but don’t want to spend a lot.

These models are made of quality steel and have traditional baffle systems. They reduce sound by 30-35 decibels and work well with many calibers. They’re reliable, not too heavy, and not too big.

They often have easy mounting systems and can be fixed. They focus on being reliable rather than having the latest tech. They meet most users’ needs at a good price.

Budget-Conscious Selections

Budget suppressors are for those who want to try out suppressors without spending a lot. They might not be as good as the others, but they’re a good start. They focus on basic functions rather than fancy features.

These models are made of aluminum or basic steel and have simple baffle designs. They reduce sound by 25-30 decibels, which is still helpful. They’re also lighter, making them easy to carry.

They might not last as long or have as many features as others. But they’re good enough for casual shooting and training. They show that you don’t need to spend a lot to get some sound reduction.

| Category | Price Range | Sound Reduction | Primary Materials | Target User |

|---|---|---|---|---|

| Premium Performance | $800-$1500+ | 35-40 dB | Titanium/Advanced Steel | Professional/Serious Enthusiast |

| Mid-Range Value | $400-$800 | 30-35 dB | Quality Steel | Dedicated Shooter |

| Budget-Conscious | $200-$400 | 25-30 dB | Aluminum/Basic Steel | Entry-Level User |

Each category meets different needs and budgets. Premium models are for those who need the best. Mid-range options are for those who want good quality without spending too much. Budget options are for beginners who want to try out suppressors without spending a lot.

Choose based on your needs, budget, and what you expect. This guide helps you find the best 30 cal suppressor for your needs and shooting style.

Maintenance Requirements and User Serviceability

Keeping your suppressor in good shape is key to its long-term performance. Different designs have different needs, affecting costs and user experience. Knowing this before you buy is important.

Suppressors come in two main types: sealed units and user-serviceable designs. Sealed ones need little upkeep but can’t be cleaned as well. User-serviceable ones can be cleaned deeply but require more work.

Cleaning Protocols and Frequency

How often you clean your suppressor depends on its design and use. It’s wise to set up a cleaning schedule based on how often you shoot and where you shoot. Different designs collect carbon at different rates.

Sealed suppressors should be cleaned every 2,000 to 5,000 rounds, depending on what you’re shooting. If you shoot a lot, you might need to clean your user-serviceable suppressor every 500 to 1,000 rounds. Shooting a lot means more carbon buildup, so you’ll need to clean it more often.

The material and coating of your suppressor affect cleaning. Titanium ones resist rust better than steel, and special coatings help with cleaning. Always use the right solvents and methods to avoid damaging your suppressor.

Disassembly and Reassembly Procedures

Good user-serviceable designs make it easy to take apart and put back together. We look at how easy it is to disassemble, what tools you need, and how well it goes back together. The best ones are easy to follow and can handle lots of maintenance.

Disassembling needs the right tools and careful attention to order. Most good suppressors come with detailed instructions. Following the manufacturer’s instructions keeps your warranty valid and prevents damage.

“The key to successful suppressor maintenance lies in understanding your specific design’s requirements and following proven procedures consistently.”

Putting it back together needs precision to keep it working right. We stress the importance of using the right torque and aligning parts correctly. If you do it wrong, you might get baffle strikes or less effective suppression.

Replacement Parts Availability

When you own a suppressor for a long time, you’ll need to think about getting replacement parts. Wear items like baffles and seals might need to be replaced. Good manufacturers offer parts support and fair prices.

We look at how well manufacturers support their parts, including their inventory, documentation, and customer service. Companies that make it easy to get parts and have good support are better for long-term satisfaction. This is important when choosing from best suppressors for sale.

Prices for replacement parts vary a lot. Shooters on a budget should consider these costs when buying. While more expensive suppressors might cost more upfront, they often have better support and lower costs over time.

Conclusion

Choosing the right 30 cal suppressor is all about finding the right mix of features. We’ve looked at how materials, design, mounting, and durability all play a part. They all add up to a great shooting experience.

When picking a suppressor, think about what you need most. Top models do well in every area, but cheaper ones might not. Knowing what you can get for your money is key.

Good suppressors work well for a long time if you take care of them. Spending more upfront means less hassle later. This guide helps you find a suppressor that fits your needs now and in the future.

Consider what you’ll use the suppressor for, how you’ll mount it, and how easy it is to clean. The best one balances sound reduction with ease of use. This makes your shooting better and more enjoyable for a long time.